WHAT WE DO

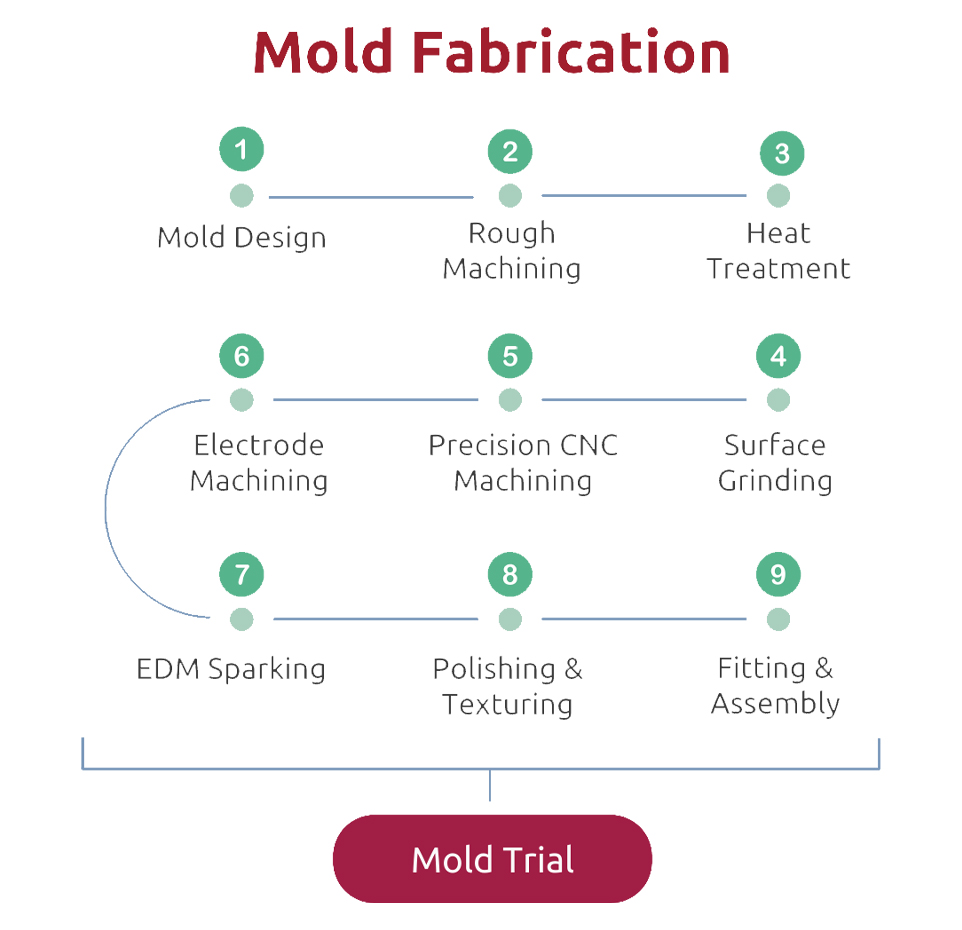

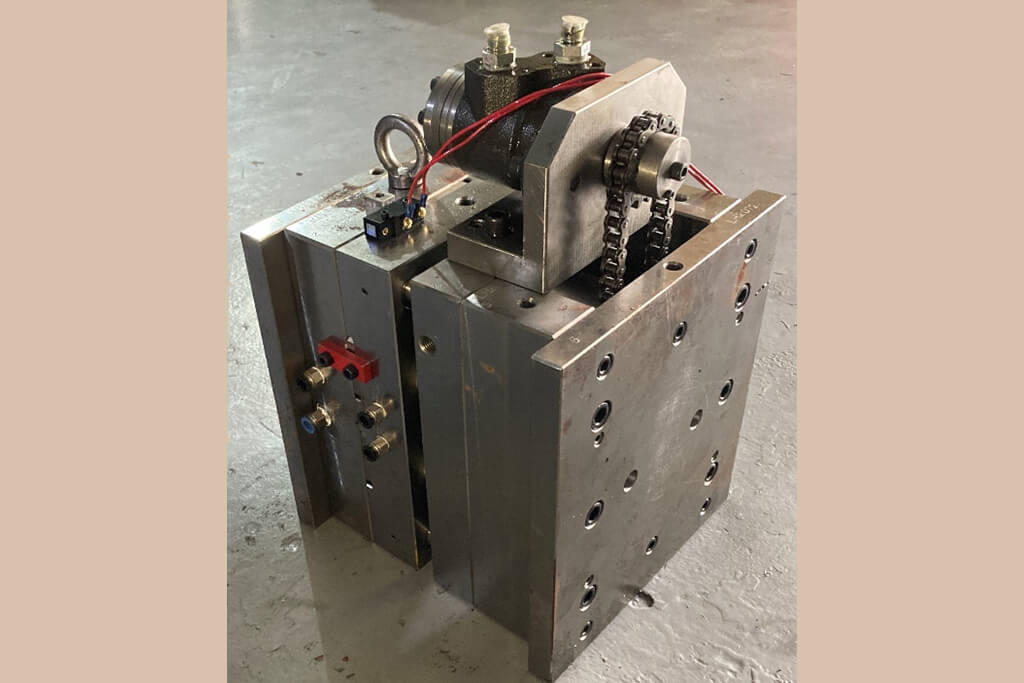

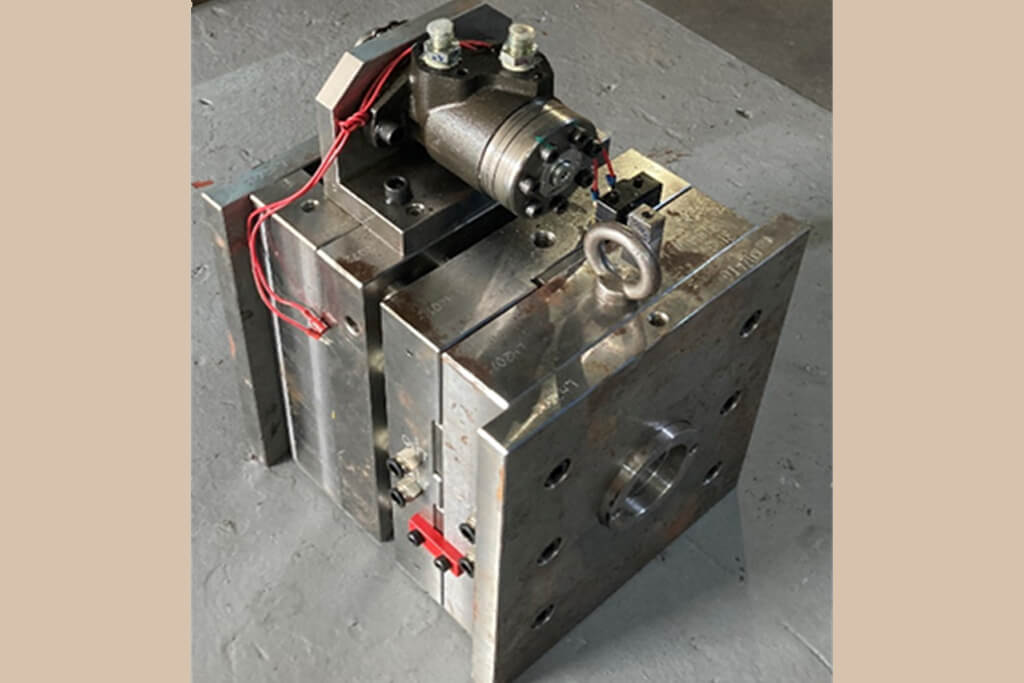

Mold Design & Fabrication

With a fully integrated 3D CAD / CAM system, our experienced mold designers and engineers can transform a highly complicated product design into a precision-finished product. The standard part data retrieving format is STEP, STL, PARASOLID, IGES, DWG & DXF.

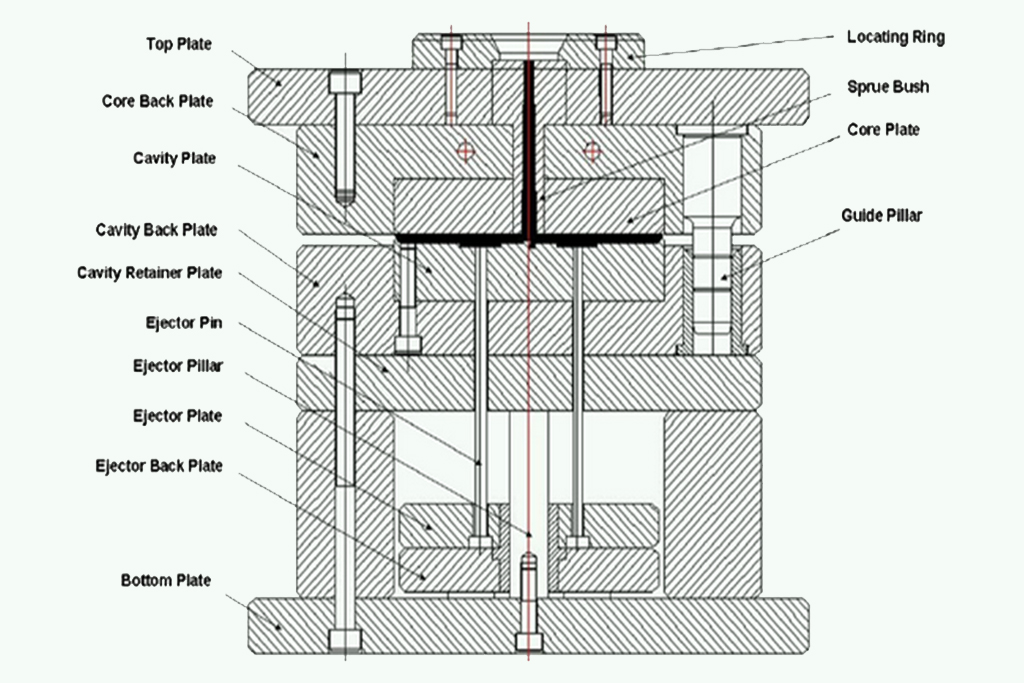

A good product derives from a well-designed mold construction. The approach of PPAP providing info lead to precise machining that determines part manufacturability and mold life cycle; the key components of mold design are of utmost importance to meet the part’s unique specifications. The mold development thru “Design for Manufacturing” gave an institution path to success.

The mold development thru "Design for Manufacturing" serves one or more purposes to increase the life of the mold and enhance the overall performance and durability of the final product.

| List Of Mold Fabrication Machineries | |||

| Nos | Descriptions | Maker | Unit |

| 1 | CNC Milling | HAAS / Fanus | 4 |

| 2 | CNC EDM | Mitsubishi | 4 |

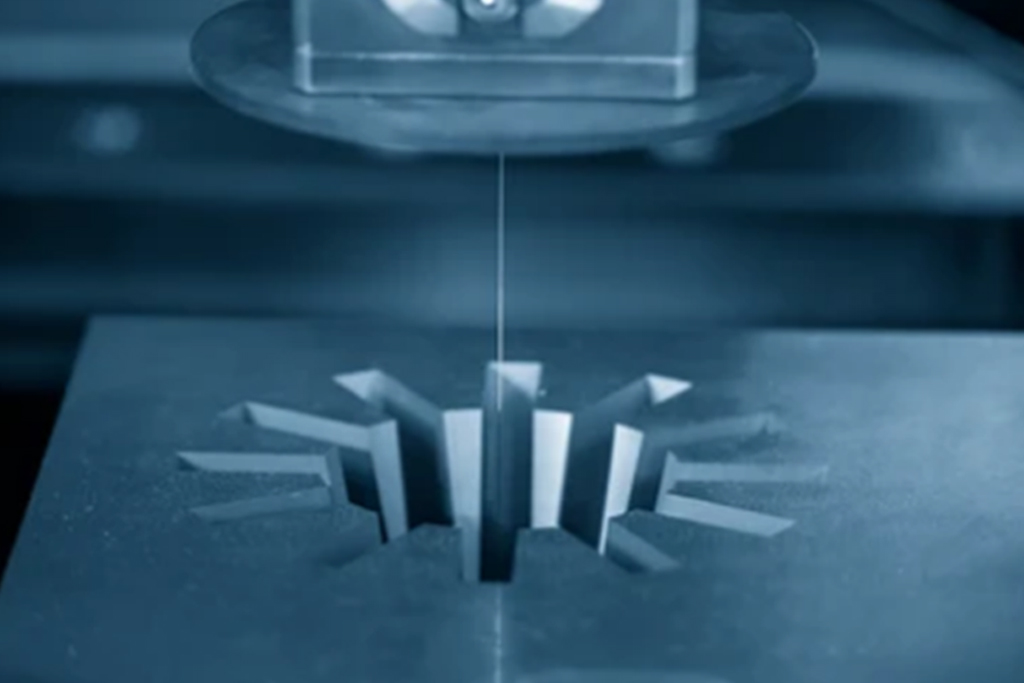

| 3 | CNC EDM Wire Cut | Sodick | 2 |

| 4 | Surface Grinding | Chevalier | 4 |

| 5 | Milling | Manford | 6 |

| 6 | CNC Drill | Zonjet | 1 |

| 7 | Turning Lathe | Yunnan | 1 |

| 8 | Radial Drill | Tone | 1 |

| 9 | Super Drill NC EDM | Tone | 1 |

| 10 | Laser Welding | Toyo | 1 |